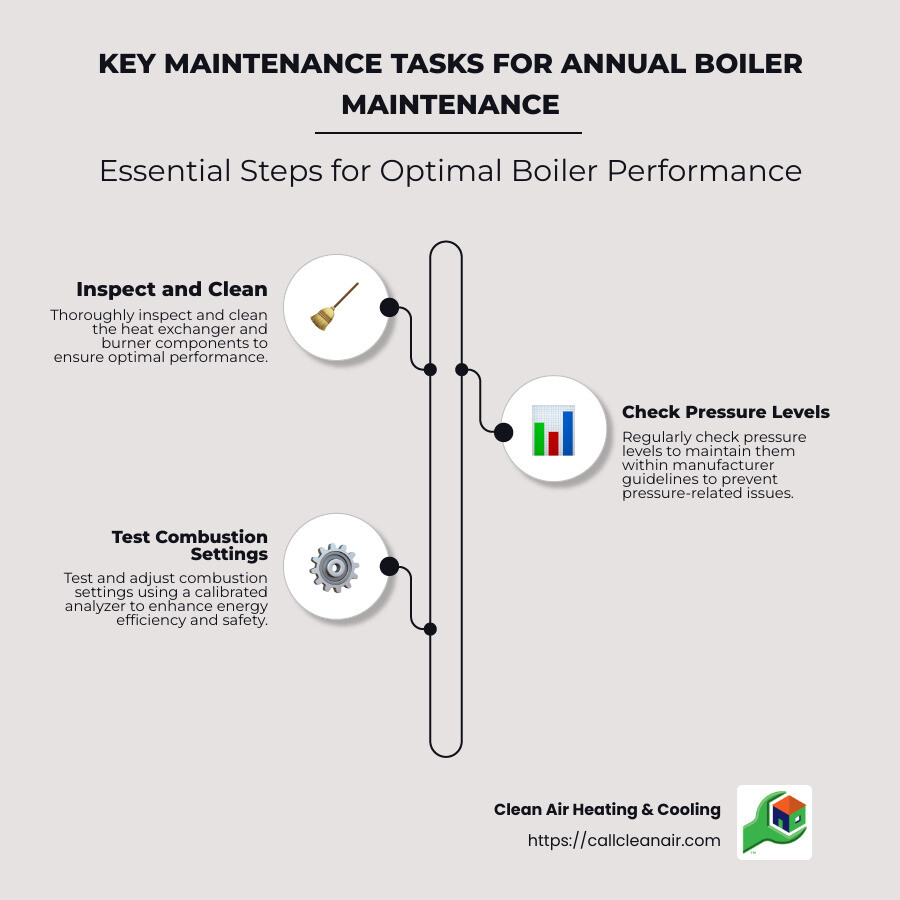

Annual boiler maintenance is essential for ensuring your heating system operates efficiently and reliably. Regular maintenance helps to prevent breakdowns, improve safety, and improve energy efficiency, ultimately reducing utility bills. Key maintenance tasks include:

- Inspecting and cleaning the heat exchanger and burner components.

- Checking pressure levels to ensure they stay within manufacturer guidelines.

- Replacing worn parts to prevent malfunctions.

- Testing and adjusting combustion settings with a calibrated analyzer.

These actions not only boost performance but also extend the lifespan of your boiler, keeping your home warm and comfortable during the colder months.

As Colin Matei, Owner and President of Clean Air Heating & Cooling, I bring years of experience in providing expert heating solutions to the Bellingham community. With an unwavering dedication to excellence in annual boiler maintenance, my team and I strive to deliver peace of mind and comfort to our valued clients.

Why Annual Boiler Maintenance is Essential

Safety First

Safety is the top priority when it comes to annual boiler maintenance. Boilers, if not maintained properly, can become hazardous. Poor maintenance can lead to defective low water cut-offs, which are a common cause of boiler incidents. These issues can result in injuries or even damage to your home. By scheduling regular maintenance, you ensure that all safety devices are functioning correctly and that potential risks are minimized.

Boosting Efficiency

A clean and well-maintained boiler runs more efficiently. During an annual service, technicians clean the heat exchanger, removing any deposits or buildup. This process improves heat transfer from combustion to water, making your system more energy-efficient. An efficient boiler not only keeps your home warm but also reduces energy consumption, leading to lower utility bills.

Extending Lifespan

Just like changing the oil in a car, regular maintenance extends the life of your boiler. By catching small issues before they become big problems, you prevent premature wear and tear. This proactive approach means your boiler will last longer, providing reliable service for many years.

Cost Savings

Preventative maintenance is often less expensive than emergency repairs. By addressing issues during a scheduled service, you avoid unexpected breakdowns that can be costly. Regular upkeep also means you’re less likely to need a complete boiler replacement, saving you even more money in the long run.

In summary, annual boiler maintenance is a smart investment. It ensures safety, boosts efficiency, extends the lifespan of your system, and saves you money.

Next, let’s dive into the key components that make up this essential maintenance.

Key Components of Annual Boiler Maintenance

Maintaining a boiler involves several crucial components. Each plays a vital role in ensuring the system runs safely and efficiently. Let’s break down these key components:

Fireside Surfaces

The fireside surfaces are where combustion occurs. Over time, soot and debris can accumulate, reducing heat transfer efficiency. Annual maintenance includes inspecting and cleaning these surfaces to prevent energy loss and ensure optimal performance.

Burner Refractory

The burner refractory material lines the combustion chamber, protecting it from extreme heat. Inspecting this material is crucial. Cracks or damage can lead to inefficient combustion and potential safety hazards. Regular checks help maintain the integrity of the boiler.

Manhole Gaskets

Manhole gaskets seal openings in the boiler, preventing leaks. These gaskets can wear out over time, leading to potential water or steam leaks. Inspecting and replacing them as needed is a key part of annual boiler maintenance.

System and Safety Valves

Valves control the flow of water and steam within the boiler. Safety valves are particularly important as they prevent overpressure conditions. Regular inspection and testing ensure these components function correctly, safeguarding the system.

Low Water Cut-Off

The low water cut-off device shuts down the boiler if water levels drop too low. This prevents overheating and potential damage. Cleaning and testing this component annually is essential for safety and reliability.

Operating Controls

Operating controls manage the boiler’s functions, such as temperature and pressure. Recalibrating these controls during maintenance ensures the boiler operates within safe and efficient parameters.

Feed Water Pumps

Feed water pumps supply water to the boiler. Overhauling these pumps annually prevents malfunctions that can disrupt the water supply, ensuring consistent operation.

Condensate Receiver

The condensate receiver collects and returns condensed steam to the boiler. Cleaning this component prevents blockages and maintains efficient water circulation.

Electrical Terminals

Electrical terminals connect the boiler’s control systems. Inspecting these connections for corrosion or damage during maintenance ensures electrical reliability and safety.

Chimneys

Chimneys vent combustion gases safely out of the building. Cleaning and inspecting chimneys annually prevent blockages and ensure proper ventilation, reducing the risk of dangerous gas buildup.

By focusing on these key components, you ensure your boiler operates safely and efficiently. Next, we’ll walk through a step-by-step annual maintenance checklist to keep your system in top condition.

Step-by-Step Annual Maintenance Checklist

Performing annual boiler maintenance isn’t just a good idea—it’s essential for safety, efficiency, and longevity. Here’s your step-by-step guide to keeping your boiler in top shape:

1. Inspect and Clean

Start by thoroughly inspecting and cleaning the fireside surfaces. This area can accumulate soot and debris, which reduces heat transfer efficiency. Cleaning these surfaces ensures that your boiler operates efficiently and saves on energy costs.

Next, check the burner refractory material. Look for cracks or damage that could lead to inefficient combustion or safety hazards. Replace any worn or damaged refractory to maintain the integrity of the boiler.

2. Recalibrate Controls

The operating controls of your boiler manage its functions, like temperature and pressure. Recalibrating these controls ensures they are set correctly, allowing the boiler to function within safe and efficient parameters. This step is crucial for optimal performance and energy efficiency.

3. Overhaul Pumps

Pay attention to the feed water pumps. These pumps are vital for supplying water to the boiler. An annual overhaul prevents potential malfunctions that could disrupt the water supply, ensuring consistent and reliable operation.

4. Clean Chimneys

Chimneys play a key role in venting combustion gases safely out of the building. Inspect and clean them to prevent blockages, which can lead to dangerous gas buildup and reduce ventilation efficiency.

5. Tune Components

Lastly, take time to tune the boiler components. This includes checking and adjusting the burner, safety and system valves, and electrical terminals. Ensuring these components are in good working order can prevent unexpected breakdowns and improve the boiler’s overall efficiency.

By following this checklist, you can keep your boiler running smoothly throughout the year, avoid costly repairs, and maximize its lifespan. Next, we’ll dive into periodic maintenance tasks that complement your annual routine.

Periodic Maintenance Tasks

While annual boiler maintenance is crucial, periodic tasks are equally important to ensure your boiler runs smoothly year-round. These tasks help catch issues early, maintaining efficiency and safety.

Oil Level

Check the oil level in the compressor lube tank daily. Use SAE 20/30 oil. Maintaining the correct oil level is vital for lubrication and smooth operation of the compressor. Low oil can lead to overheating and damage, while too much oil can cause leaks.

Air Filters

Keep air filters clean. Clogged filters can lead to an improper air/oil mixture, causing carbon build-up and inefficient combustion. Check and clean these filters regularly to ensure optimal airflow and prevent performance issues.

Water Cut-Offs

Flush the low water cut-offs twice a week. This helps prevent sediment buildup, which can interfere with the cut-off’s operation. Make sure to perform this while the burner is on and a flame is present. The flame should extinguish during the flush, indicating that the cut-off is functioning properly.

Blowdown

Conduct a boiler bottom blowdown monthly or as needed. This process clears sludge and sediment, helping to control water quality and chemical treatment concentrations. Regular blowdowns are essential to prevent corrosion and prolong the boiler’s life.

Water Monitoring

Monitor the make-up water being added to the boiler. An excess amount of fresh water can indicate a leak in the system and introduce oxygen, which is detrimental to boiler components. Keeping an eye on water usage can help detect issues early.

Smoke Alarm

Check the smoke alarm weekly. Wipe the light source and receiver to ensure accurate readings. Set the unit in line with local standards, avoiding the highest setting. Regular checks ensure the alarm functions correctly, providing an essential safety measure.

By integrating these periodic tasks into your maintenance routine, you can improve the reliability and efficiency of your boiler system. Next, we’ll address some frequently asked questions about annual boiler maintenance.

Frequently Asked Questions about Annual Boiler Maintenance

What maintenance is required on a boiler annually?

Annual boiler maintenance is essential to keep your system running efficiently and safely. Key tasks include inspecting and testing safety valves, which prevent over-pressurization by automatically releasing excess pressure. The gas regulator also needs checking to ensure it maintains the correct gas pressure for optimal combustion.

Safety shut-off valves are another critical component. These valves stop the gas supply if a problem is detected, preventing potential hazards. Regular maintenance of these parts not only improves safety but also boosts the system’s efficiency and lifespan.

Does a boiler need to be serviced every year?

Yes, servicing your boiler annually is vital. This routine maintenance ensures the boiler operates at peak efficiency, which can reduce energy consumption and lower utility bills. An annual check-up catches potential issues early, preventing costly breakdowns and prolonging the boiler’s lifespan.

Safety is another reason for yearly servicing. Technicians inspect and maintain all safety features, reducing the risk of malfunctions or hazards. As a bonus, many manufacturers require annual maintenance to keep warranties valid.

How much does a boiler service cost?

The cost of a boiler service can vary based on the service type and your location. Typically, a standard annual service includes inspection, cleaning, and minor repairs, all of which contribute to maintaining efficiency and safety.

While specific pricing information isn’t provided, investing in regular maintenance can save you money in the long run by avoiding emergency repairs and extending the life of your boiler. Always consult with a professional to understand the best service options for your needs.

By addressing these common questions, we hope to clarify the importance of annual boiler maintenance and encourage proactive care for your heating system. Next, let’s explore how Clean Air Heating & Cooling can help ensure your boiler remains in top condition.

Conclusion

When it comes to keeping your home warm and cozy, Clean Air Heating & Cooling is your trusted partner for all things related to boiler maintenance. Based in Bellingham, WA, we proudly serve the communities of Whatcom, Skagit, Snohomish, and San Juan Counties. Our commitment is to provide prompt, high-quality service that focuses on your satisfaction.

Customer Satisfaction is at the heart of everything we do. With over 480 5-star Google reviews, our track record speaks for itself. We believe in taking care of our neighbors by ensuring their heating systems are running safely and efficiently. Our team of experts is always ready to address your concerns and provide solutions custom to your needs.

One of the unique benefits we offer is our 25% utility savings guarantee. Regular maintenance not only keeps your boiler in peak condition but also helps reduce energy consumption. By optimizing your system’s performance, you can enjoy lower utility bills while maintaining a comfortable indoor climate.

Investing in annual boiler maintenance with us means peace of mind. Our experienced technicians will conduct thorough inspections and tune-ups to extend your boiler’s lifespan and prevent unexpected breakdowns. This proactive approach saves you money in the long run and ensures your home stays warm during the cold months.

Ready to schedule your annual maintenance or have questions about our services? Visit our Bellingham Boiler Service page to learn more and book an appointment. Let us help you keep your heating system running smoothly all year round.