Why Understanding Mini Split Error Codes Can Save You Time and Money

A mini split error code is a diagnostic tool that tells you what’s wrong with your system, helping prevent small issues from becoming expensive repairs. These codes appear on the indoor unit or remote when sensors detect problems with pressure, temperature, or other functions.

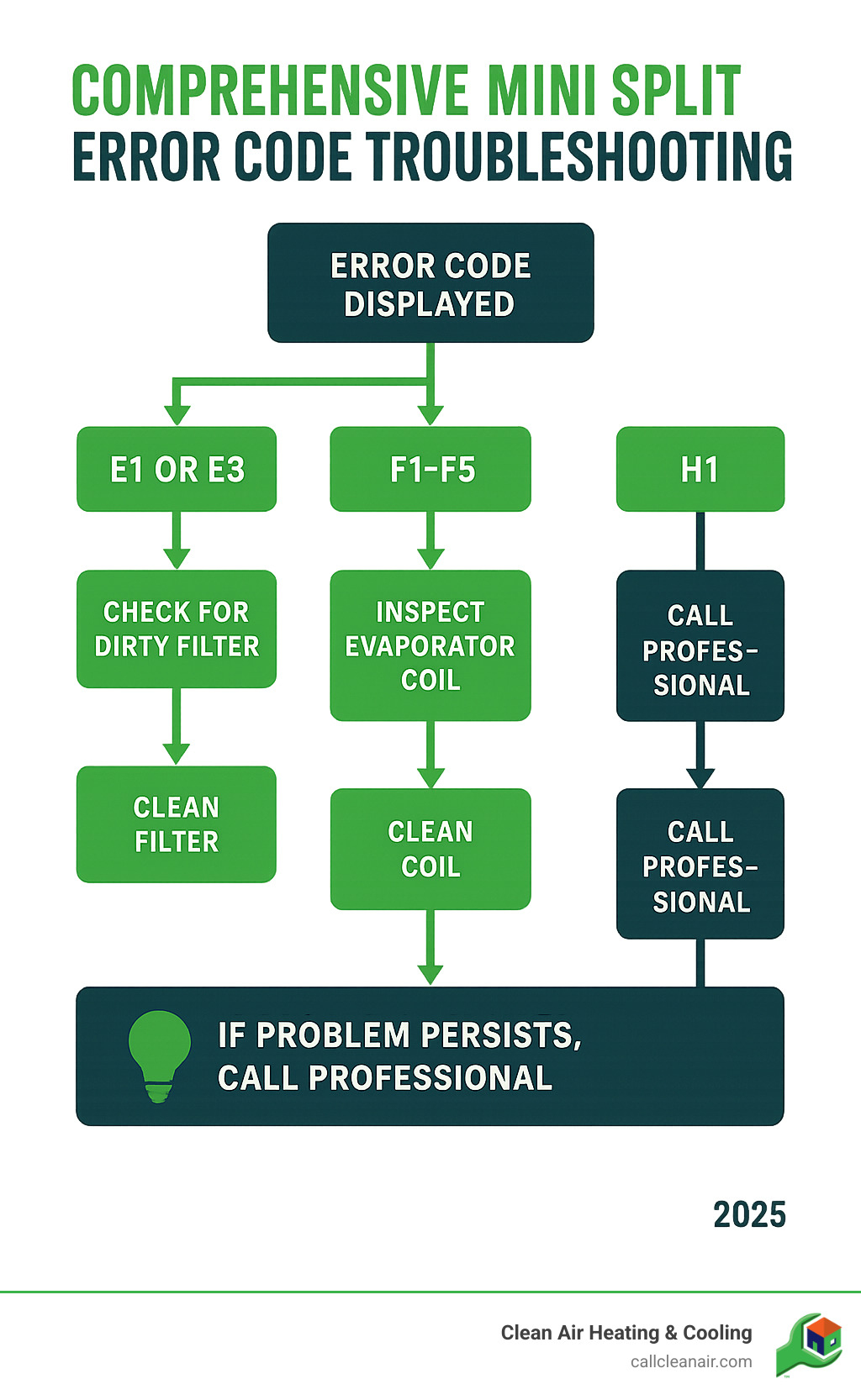

Most Common Mini Split Error Codes:

- E1/E3 – High or low pressure issues (often dirty coils or refrigerant problems)

- F1-F5 – Sensor malfunctions (temperature sensors not reading correctly)

- H1 – Defrost mode (normal operation in cold weather)

- H5/P0 – Power module protection (electrical issues)

- E6/EL01 – Communication errors between indoor and outdoor units

- CL – Filter cleaning reminder (maintenance alert, not an error)

Think of these codes as an early warning system, similar to a car’s check engine light. Ignoring them can lead to major breakdowns, but many codes indicate simple DIY fixes, like cleaning filters or clearing debris from the outdoor unit.

When Error Codes Become Serious

Some codes indicate problems that need immediate professional attention. Refrigerant leaks, electrical faults, or compressor issues can damage your system permanently if not handled correctly. Understanding which codes you can tackle and which require expert help protects both your safety and your investment.

As Colin Matei, owner of Clean Air Heating & Cooling, I’ve seen how understanding mini split error codes helps Whatcom County homeowners prevent costly emergency repairs by addressing minor issues early.

Mini splits are popular for their energy efficiency and zone-specific temperature control. Understanding their basic components—an indoor unit and an outdoor unit connected by refrigerant lines—is key to troubleshooting. For a deeper dive, see our guide on How Do Mini Splits Work in Your Home?

First Steps: Basic Troubleshooting for Any Error Code

When a mysterious code appears, don’t panic. Many mini split error codes can be resolved with simple troubleshooting.

Start by power cycling your system, which can clear temporary glitches. Turn the unit off via the remote, then reset the breaker at your electrical panel. Wait 10 minutes before turning it back on to allow the system to fully reset.

Before assuming a major fault, check your remote control batteries. Weak batteries can send faulty signals and trigger error codes.

Airflow is critical, so inspect your air filters first. Clogged filters strain the system and can trigger pressure-related errors. Clean reusable filters with lukewarm water or replace disposable ones.

Next, perform an outdoor unit inspection. Debris removal is crucial, so clear away leaves, grass, and other blockages. Also, check for obstructions like overgrown shrubs that might impede airflow.

These basic steps resolve many common mini split issues and are worth trying before looking up specific codes.

What are Normal System Messages?

Not every code or light indicates a problem. Some messages are part of normal operation.

The CL code is a simple filter cleaning reminder. It appears after a set number of operating hours and disappears once you’ve cleaned the filter.

Defrost mode (often an H1 code) is a normal function in cold weather. You may see steam from the outdoor unit as it melts ice from its coils. This cycle is essential for efficient heating and usually lasts 5-15 minutes.

Your mini split also uses standby lights and blinking lights to indicate different states. A steady green light usually means normal operation, while blinking patterns can signal heating, cooling, or standby modes.

Remember: not all codes are errors. Check your owner’s manual to distinguish between normal messages and actual problems.

Understanding Your Mini Split Error Code: Common Categories and Meanings

Mini split error codes follow a logical pattern. The first letter often indicates the problem category, making troubleshooting easier. Understanding the fundamentals of mini split systems helps you grasp why these categories exist.

Here’s a breakdown of common error code prefixes:

| Code Prefix | What It Usually Means |

|---|---|

| E | Pressure problems, system errors, or communication hiccups |

| F | Temperature sensors acting up |

| P | Protection modes kicking in, compressor troubles, or power issues |

| H | Defrost cycles or power module protection |

| C, L, U | Specific electrical, voltage, or configuration problems |

For example, an F2 code points to sensors, while a P4 suggests a compressor or power supply issue. While patterns are consistent, specific codes vary by brand, so always consult your owner’s manual. Knowing the general categories helps you understand the mini split error code and decide if it’s a DIY fix or a job for a pro.

What to Do for a Pressure-Related Mini Split Error Code (E-Series)

E-series error codes usually indicate pressure problems within the refrigerant system. When the balance between high and low pressure is disrupted, system performance suffers.

High pressure issues (E1 codes) often mean the system can’t expel heat effectively. The most common cause is a dirty outdoor unit, where grime on the condenser coils prevents proper heat transfer. Other causes include blocked airflow around the outdoor unit, an overcharged refrigerant system, or a failing outdoor fan.

Low pressure problems (E3 codes) mean there’s not enough refrigerant circulating or its flow is blocked. Common culprits are severely clogged indoor air filters. More serious causes include refrigerant leaks or frozen evaporator coils. If you see ice, turn the unit off to let it thaw.

For E-series codes, start by cleaning air filters and clearing debris from the outdoor unit. If the code persists or you suspect a refrigerant issue, call a professional, as refrigerant work is not a DIY job.

How to Address Sensor Malfunctions (F-Series)

F-series error codes appear when temperature sensors provide incorrect readings. A malfunction prevents the system from maintaining the correct temperature.

- F1 codes point to the indoor ambient sensor, which reads your room’s temperature.

- F2 codes involve the indoor coil sensor, which monitors the evaporator coil’s temperature.

- F3 codes signal trouble with the outdoor ambient sensor, which is crucial for heating and defrost cycles.

- F4 codes indicate issues with the outdoor coil sensor.

- F5 codes usually mean the compressor’s discharge sensor has a problem, which can signal serious compressor strain.

Troubleshooting sensor issues starts with checking for loose connections or dirty sensors. A gentle cleaning may resolve the issue. However, most sensor problems require professional diagnosis and replacement. Regular Mini Split Cleaning Service can help catch these issues early.

Decoding Power, Communication, and Protection Codes (P, H, U, C, L Series)

Codes in the P, H, U, C, or L series often indicate more serious problems. These mini split error codes point to electrical faults, communication failures, or protective shutdowns designed to prevent system damage.

- Communication errors (E1, E6, or EL 01) mean the indoor and outdoor units cannot coordinate. This often results from loose wiring, damaged cables, or electrical interference.

- H1 codes usually mean the system is in defrost mode, which is normal. If it gets stuck in this mode, it could signal a sensor problem.

- IPM protection codes (H5 or P0) indicate the Intelligent Power Module has detected dangerous conditions like voltage irregularities or overheating and has entered a safe mode.

- Compressor-related codes (P4 or P6) signal issues with the compressor, possibly due to high temperatures or electrical faults.

- Voltage and power supply issues (P1 or U3) mean the electrical supply is unstable.

- C5 codes often relate to jumper configuration issues, while L9 codes indicate power protection activation.

These complex codes typically require professional diagnosis. While you can try power cycling the system, persistent codes in these series are a clear sign to call an expert.

Proactive Care: How Preventive Maintenance Minimizes Errors

Preventing mini split error codes is better than fixing them. Regular maintenance is one of the best investments for your home comfort system.

Regular maintenance extends your system’s lifespan, maintains peak efficiency for lower energy bills, and reduces surprise mini split error code appearances. It helps catch small issues before they become expensive problems.

Many impactful maintenance tasks are simple. Cleaning or replacing air filters regularly is the easiest way to prevent problems. Clogged filters cause system strain, which can trigger E3 (low pressure) or F-series (sensor) errors. A monthly check can prevent this.

Your coils need love too—both indoor and outdoor. When they get dirty, efficiency drops, and you may see pressure errors like E1 or E3. While you can gently brush off the outdoor coil, deep cleaning is best left to professionals.

Ensure clear drainage from the indoor unit. A clogged condensate drain line can cause water to back up, leading to potential water damage.

Keeping your outdoor unit breathing freely is also crucial. Obstructions from shrubs or leaves can cause overheating and trigger E1 or H5 protection codes.

While these DIY steps are valuable, nothing replaces a professional annual tune-up. Our technicians perform comprehensive checks, including testing refrigerant levels, electrical connections, and calibrating sensors to catch problems early.

Investing in regular Mini Split Maintenance protects your comfort and peace of mind, preventing unwelcome mini split error code surprises.

When to Stop Troubleshooting and Call a Professional

While many troubleshooting steps are DIY-friendly, some mini split error code situations require professional expertise. Knowing when to call an expert is key.

- Safety first: If you smell burning wires, see sparks, or notice other electrical issues, turn the unit off at the breaker and call a professional immediately. These are signs of dangerous conditions.

- Refrigerant-related problems: These require a professional. Low pressure codes (E3) can indicate a leak, and handling refrigerant requires special tools and licensing. It is not a safe DIY task.

- Complex electrical error codes: Codes like H5, P1, P4, P6, U3, or C5 point to internal component failures. These require a certified technician with specialized testing equipment to diagnose and repair.

- Persistent error codes: If you’ve tried basic troubleshooting and the mini split error code returns, an underlying problem needs expert diagnosis.

- Unusual noises or smells: Grinding, hissing, or buzzing sounds, along with burning odors, are red flags for serious mechanical or electrical problems.

- Visible leaks: Any water leaks (beyond normal condensation) or signs of refrigerant leaks (like ice on the lines) require professional intervention.

- System won’t turn on: If the unit has no power after basic checks, you likely have a significant electrical or control board issue.

Improper service can cause property damage or personal injury. When in doubt, calling a professional protects you and your investment. Our team at Clean Air Heating & Cooling specializes in diagnosing and resolving tricky mini split problems. For expert help in the Bellingham area, explore our services from leading Mini Split Installation Companies.

Frequently Asked Questions about Mini Split Faults

How do error codes differ between brands like Lennox, Gree, or Mitsubishi?

While many brands use similar patterns (e.g., ‘E’ for pressure), each manufacturer has unique mini split error codes. For example, an E1 code on a Lennox unit might mean a communication error, while on a Gree system, it could indicate high pressure. Pioneer, Senville, and Daikin also have unique codes. While basic troubleshooting like cleaning filters and checking power applies to all brands, your model’s manual is necessary for an accurate diagnosis.

Can I just reset my mini split to clear an error code?

Yes, resetting your unit at the breaker can clear temporary glitches. However, if the mini split error code returns, it indicates a persistent underlying problem that needs to be addressed. Ignoring a persistent code is like ignoring a check engine light—the problem can worsen. These codes are protective features. Always write down the code before resetting, as this information is valuable for a professional technician.

What does a blinking green light mean on my mini split?

A blinking green light can mean many things depending on the brand and model. It could indicate standby mode, a normal defrost cycle, a filter cleaning reminder, or a communication error. Because there is no universal standard for blinking lights, your owner’s manual is the best tool for translating what your specific unit is trying to communicate. Understanding its unique language turns mysterious signals into helpful status updates.

Your Partner for a Healthy HVAC System

Understanding mini split error codes empowers you to handle common issues, from cleaning a filter for an E3 code to recognizing an H1 code as a normal defrost cycle. You can now approach these situations with confidence.

The best way to avoid error codes is through prevention. Regular maintenance, including simple tasks like cleaning filters and clearing debris from the outdoor unit, is your best defense against breakdowns and costly repairs.

However, some issues require a professional. For persistent codes, electrical problems, or refrigerant issues, calling an expert is the smart choice to protect your safety and your investment.

If you’re dealing with a stubborn error code or want to schedule professional maintenance, the certified technicians at Clean Air Heating & Cooling are here to help. We serve families throughout Whatcom, Skagit, Snohomish, and San Juan Counties and understand the frustration of a malfunctioning comfort system.

Our team doesn’t just fix problems; we explain the cause and how to prevent it in the future. With over 480 five-star Google reviews, we have a reputation for prompt, high-quality service that solves the problem correctly the first time.

Ready to restore your home’s comfort? Explore our comprehensive mini split services and learn how we can get your system back to peak performance.